Alkaline Protease

Introduction

The Alkaline Protease is a solid enzyme produced by submerged fermentation. It is widely applied in detergent, leather depilation and softening, silk degumming, heparin sodium, chondroitin etc.

Activity Definition

One unit of Alkaline Protease is defined as the quantity of enzyme, which liberates1μg tyrosine from casein at 40℃ and pH10.5 in 1min.

Characteristics

Alkaline Protease can efficiently hydrolyze the protein into free amino acids.

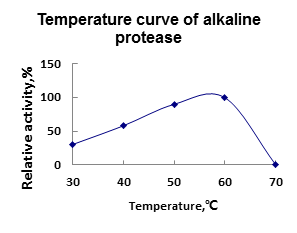

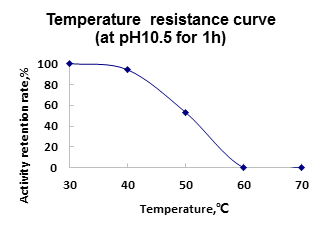

Effective temperature: 20-65°C, Optimum 40-50°C

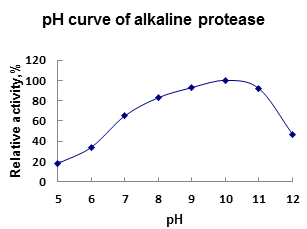

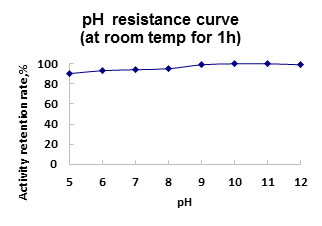

Effective pH: 8-12, Optimum 9-11

Specification

|

Appearance |

Light yellow or brown powder |

|

Odor |

Normal fermentation odor |

|

Enzyme Activity |

100,000U/g 200,000U/g |

|

Particle size |

≥90% pass 40 mesh sieve |

|

Water content |

≤ 8% |

Application & Reference Dosage

1. Heparin Sodium:

(1). Add salt and alkali at earlier stage. The process is the same with salt dissolving.

(2). Rise the low temperature to 65°C and keep 1 hour.

(3). Cool down the temperature to 45°C and add 3g enzyme powder (100,000 u/g) for one piece of small intestine.

(4). Rise the temperature to 60°C after adding the enzyme and keep 4-6 hours.

(5). Filtering after rising the temperature to 80°C.

(6). Add Resin when the temperature is cooled down to 60°C after the filtering.

(7). The procedure of dissolving salt is different.

Adjust the dosage and the enzymolysis condition according to the quality of raw materials and the practical production conditions.

2. Chondroitin

(1). Stir the enzyme well with water, and then add it into the materials.

(2). Add 0.4%-0.6% of enzyme powder during the whole process of enzymolysis dissolution. Add the enzyme separately by twice. Add 60-70% of the total enzyme in the front two thirds time and add the rest enzyme during the left time.

(3). Enzymolysis condition: Adjust the temperature to 45-60°C and pH at 10.5. Process time: 5-8 hours. Stir once every 30mins.

Adjust the dosage and the enzymolysis condition according to the quality of raw materials and practical production condition.

3. Pretreatment in Silk Degumming:

Pretreatment → Dehydration → acid treatment (add protease 18-24 u/ml and soap 0.75% at 48-50°C and pH 10.5) → Dehydration → skin tearing off → washing →Dehydration → fluffing → drying → fluffing

4. Leather Depilation:

Raw Hides → washing → degreasing → alkali expansion → feather plucking → splitting → dealkalization → enzyme depilation → washing → pickling →tanning.

Features:

Simplify production process and reduce production period.

Improve end product quality, leather yield and reduce production cost.

No pollution to the equipment, environment and leather.

Environmental-friendly & bio-degradation

5. detergent:

Decompose protein based stains like grass, blood, mucous, milk, meat, faecal material, human sweat and etc. into small, readily soluble peptides and amino acids which can be easily removed during washing process and thus improving the cleaning efficiency of detergents.

Add Alkaline Protease in the toothpaste, toothpowder, Mouth Refreshner can contribute to tartar removing.

Shelf Life & Storage

25℃, 12 months at room temperature.

Store in a dry and cool place, avoid toxic and hazardous materials. Seal up bag after each use.

Packaging

Powder: 20kg/bag.